Grinding Balls

Grinding balls, which are also known as Milled balls, Steel balls and Grindind balls. In English, these balls are called GRINDING BALLS. These parts are used in grinding mills in cement, mining and steel industries.

Buy Gringing Balls

On this page, you can see all the information related to Grinding Balls and call 09132121860 to get the price and buy them.

Types of grinding balls

The grinding balls produced by Iranzob Company are divided into the following 3 categories:

| First category | Chromed grinding balls used in the cement industry, some mines and dry grinding, sizes: 15, 17/5, 20, 25, 30, 40, 50, 60, 70, 80, 90, 100, 125 mm |

| The second category | High chromium cast iron balls used by steel factories (Mubarakeh, Ahvaz) in sizes 30, 40, 50 mm and up to 30% chrome. |

| The third category | Low chrome bullets. These grinding balls are one of the inventions of Iran Zob Company, which was introduced to the country’s mines in 1379. This product is known as white cast iron grinding balls and is competitive with forged grinding balls in terms of price and quality. This product is mainly suitable for ballmils. The sizes of these grinding balls are: 25, 30, 35, 40, 50, 60, 70, 80, 90, 100 mm. |

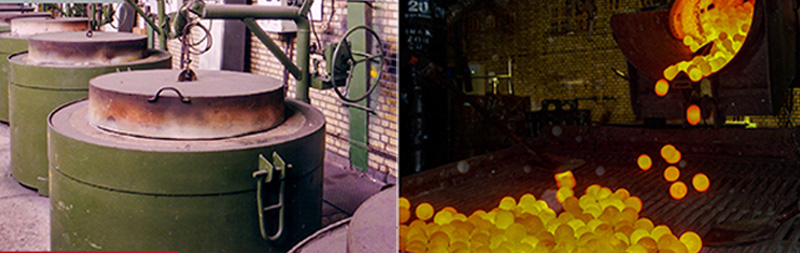

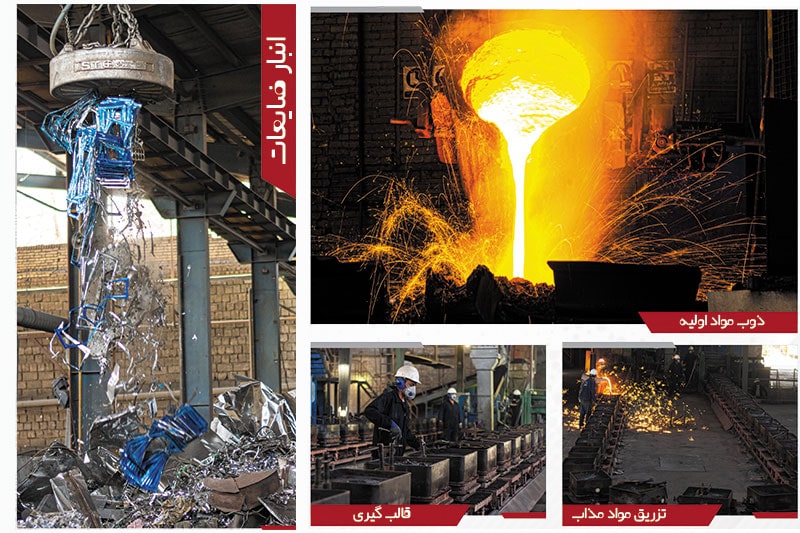

Grinding Balls Production Steps

The most important raw materials for casting grinding balls and steel parts are cast iron, scraps and metal scraps. These materials along with ferroalloys such as ferrochromium, ferrosilicon, manganese form, as well as foundry sand, bentonite, silicate glue, etc., in a large volume, after being approved by the quality control unit, entered the warehouse of the Iranian factory to be melted and melted. Castings are sent to production units.

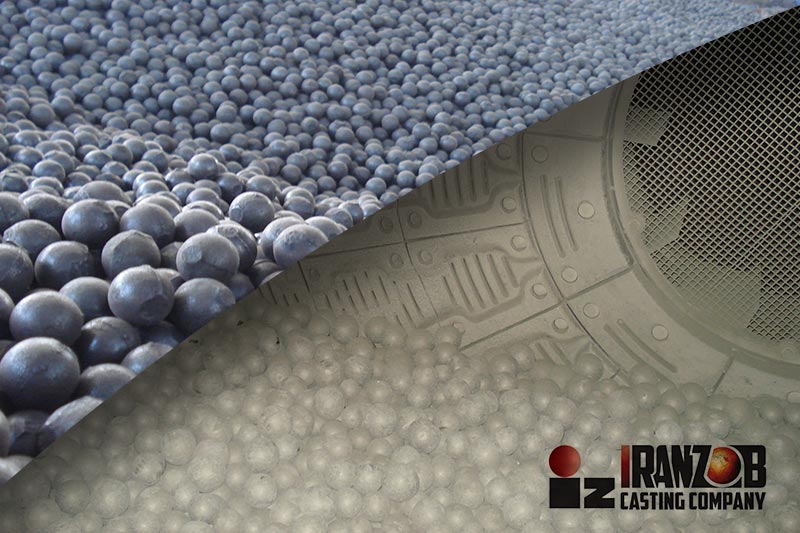

In this production hall, mainly anti-wear balls made of high-chrome cast iron or white cast iron from 15 to 125 mm in diameter are produced by a semi-automatic molding line using the sand method. This unit has 3 pairs of induction furnaces with capacities of 1, 1.5 and 3 tons.

Depending on the analysis of the required product, furnace operators charge scrap, ferroalloys and other required raw materials in furnaces with a temperature of about 1500 degrees Celsius, and melting is done.

After the completion of the process of melting and making sand molds in the molding line, if the temperature, analysis and strength of the molds are confirmed by the quality control unit, the permission for melting is given and the melt is transferred from the furnace to the melting pans and from the pan to the It is poured into molds.

After filling and completing the freezing process, these molds go to the discharge part of the grade and from there, after separating and recycling their sand, they are transferred to the vault to cool and separate the feed and channel. Finally, the produced pellets are milled and sent to the pelletizing and heat treatment hall for separation from each other and heat treatment.

Heat treatment and finishing unit

Also, tensioning in rotary kilns causes that, in addition to achieving the desired surface quality, the thermal residual stresses created in the casting and quenching stages of the pellets are eliminated and their useful life is increased. Heat treatment and tensioning in metal barrels and parts are packed in wooden pallets and ready to be shipped

Quality control unit and laboratory of Iran Zob factory

Using all the necessary equipment, this unit conducts necessary tests to control the quality of the process. The laboratory of Iran Zob Company, using devices such as quantometry, hardness metallography, etc., as well as devices for testing strength, gas and moisture passage, and sand granulation, from the beginning of the arrival of the raw materials to the moment of the product’s departure under its supervision. and has made all the processes related to production clear, and finally, after passing all these steps and performing PT, UT, MT, etc. tests, if approved, he issues the license to send the product.

The laboratory of Iran Zob Company has the ES 856 certificate from the Standard and Industrial Research Department of Isfahan province and is known as a reference laboratory in the country.

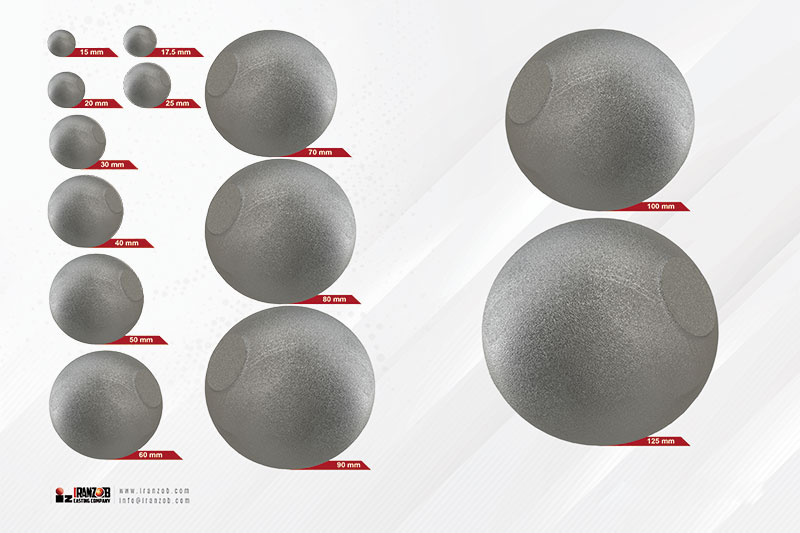

Dimensions of Grinding balls

In the Iranian factory,Grinding balls is produced from 25mm to 125mm.

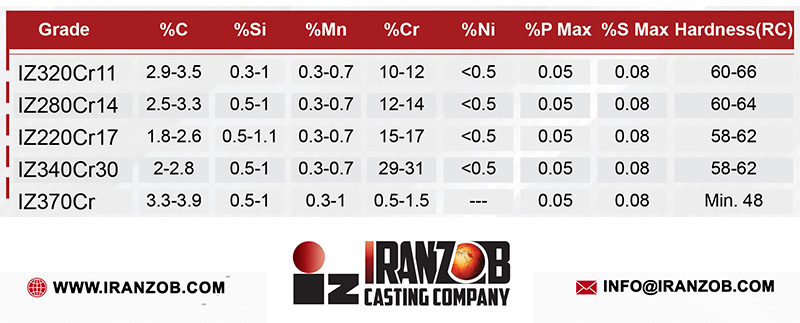

| Dimensions of Grinding balls | |

| (۶۰-۶۶ HRC) | IZ320Cr11 15-17.5-20-25(mm) |

| (۶۰-۶۴ HRC) | IZ280Cr14 30-35-40-50(mm) |

| (۵۸-۶۲ HRC) | IZ220Cr17 60-70-80-90-100-125(mm) |

| (۵۸-۶۲ HRC) | IZ340Cr30 30-40-50(mm) |

| (Min.48 HRC) | IZ370Cr 25-30-35-40-50-60-80-100(mm) |

Application of Grinding balls

Grinding balls are usually used in various industries to grind and mix materials. Some common uses of ball mills are:

- Cement Industry: Grinding balls are used to grind cement clinker into powder for cement production.

- Mining Industry:Grinding balls are used to grind ore and other materials to process minerals such as gold, silver, copper and other metals.

- Chemical Industry: Grinding balls are used to mix and grind chemicals to produce various products.

- Pharmaceutical industry:Grinding balls is used to grind drugs into fine powder so that they are more easily absorbed by the body.

- Food industry: Grinding balls is used to grind food products such as cocoa powder, spices and coffee beans.

- Ceramic Industry: Grinding balls are used to grind and mix ceramic materials to produce tiles, pottery and other products.

- Powder metallurgy: Grinding balls are used to grind metal powders into fine particles for use in manufacturing.

In general, Grinding balls are versatile machines that can be used for a variety of applications in various industries, where materials must be ground and mixed to achieve a specific particle size or other physical properties.

The type of Grinding balls

Anti-wear cast iron ball

The anti-wear cast iron ball is one of the inventions of Iran Zob company and is made of white cast iron with a small amount of chromium, which is very competitive with forged balls in terms of price and quality. These pellets are mainly recommended in mining industries that have a high consumption volume. These balls are used in ball mills and are also known as metal balls or grinding balls.

Production of Grinding balls in Iran Zob factory

Iran Zob Company is the first and best producer of Grinding balls in Iran. These pellets are made of high-chrome cast iron with anti-wear properties and are the most important production products of Iran Zob Company, with about 40 years of experience. The metal balls of Iran Zob company have the lowest amount of wear compared to other similar samples in the market and can compete with the balls produced by reputable companies in the world such as Mogato Belgium.

According to customers, Iran Zob Company has a record wear rate of 6.3 grams per ton, which is much better than the global standard set for this product.

Factory Address: Isfahan – Zob Ahan Highway – Oshtorjan Industrial Town – Sixth Street – No. 57 Iran Zob Factory

Office Address: Isfahan – University Street – 13 Alley (Shaheed Khoshab) – No. 28 – Iran Zob Building

Contact us for a free consultation...